Highlights of Project Economics and Key Parameters:

|

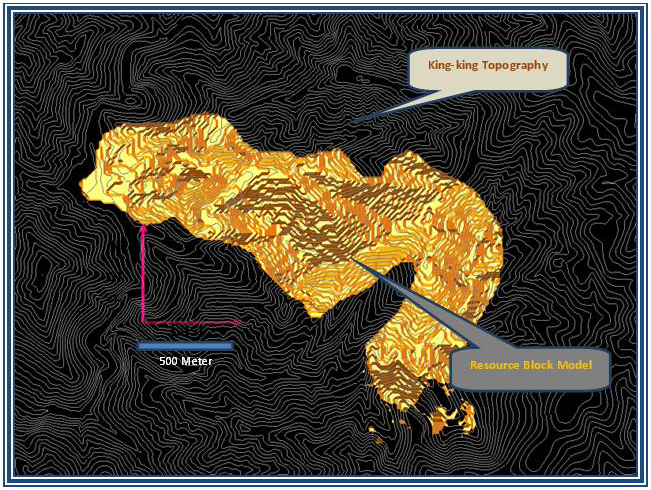

The King-king tenement is comprised of 184 mining claims that are owned by Nationwide Development Corporation (NADECOR) under Mineral Production Sharing Agreement #009-92-XI (the MPSA), approved by the Government of the Philippines on May 27, 1992, and amended December 11, 2002.The MPSA grants the exclusive right to explore, develop and exploit minerals within the area comprising the King-king deposit.The project is listed as one of the top priority projects by the Philippine Mines and Geosciences Bureau and it is a gold-rich porphyry copper deposit spatially related to significant epithermal vein systems that can be potentially exploited by open pit mining methods to produce economic concentrations of gold and copper. |

Reserve Base

The table below presents the mineral reserve for the King-king Project based on the mine and plant production schedules developed for the feasibility study. The mineral reserve amounts to 617.9M tonnes at 0.300% total copper and 0.395 g/t gold.

|

Mining Schedule & Development Process

|

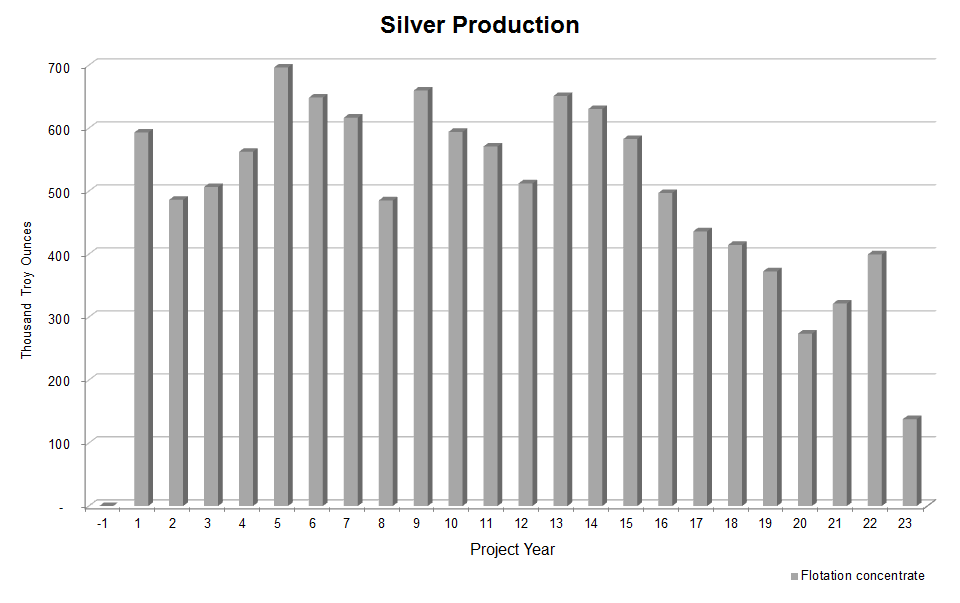

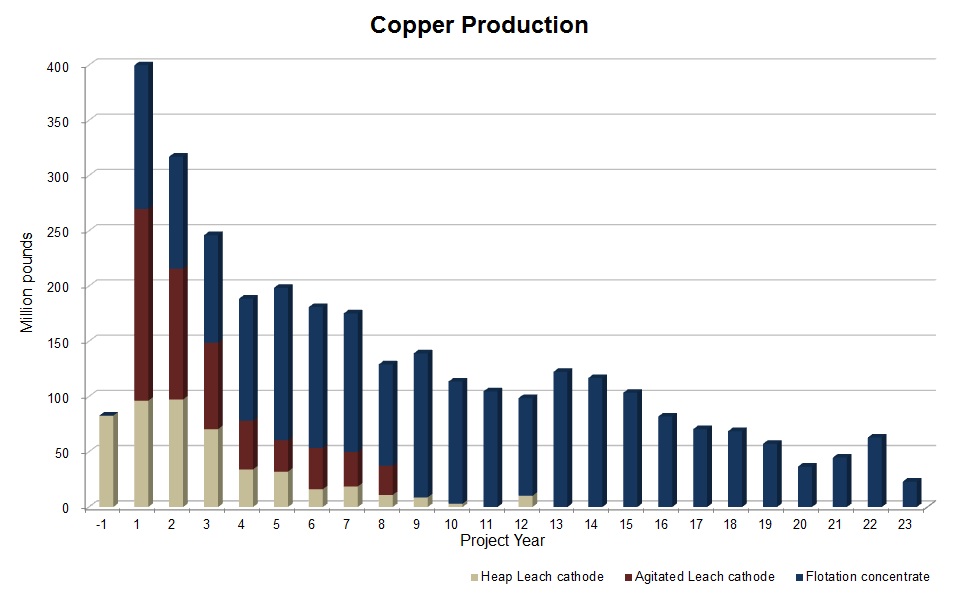

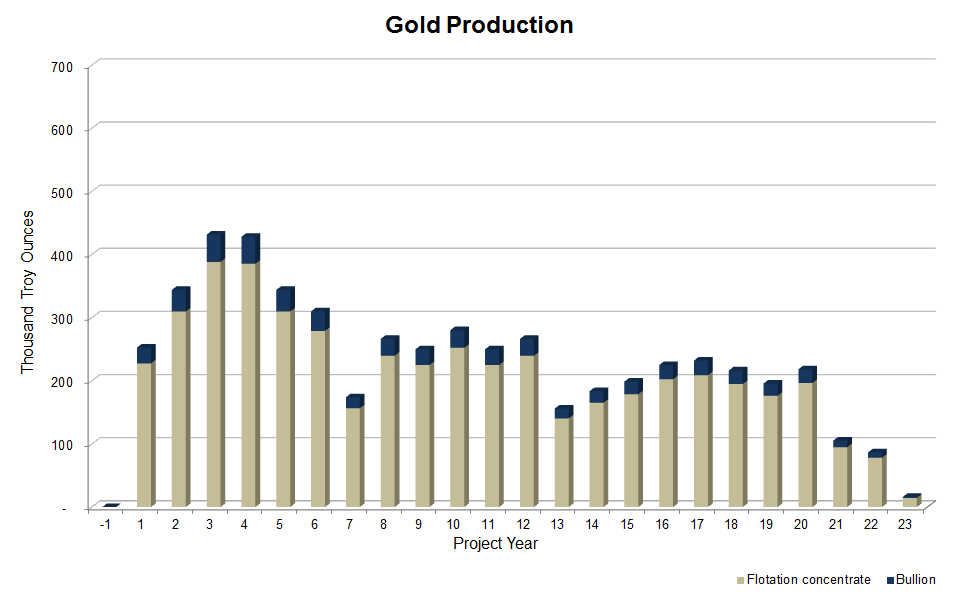

The proposed open-pit mine will produce copper/gold/silver concentrate, copper cathode, and gold doré bullion. On average, the mine will annually produce:

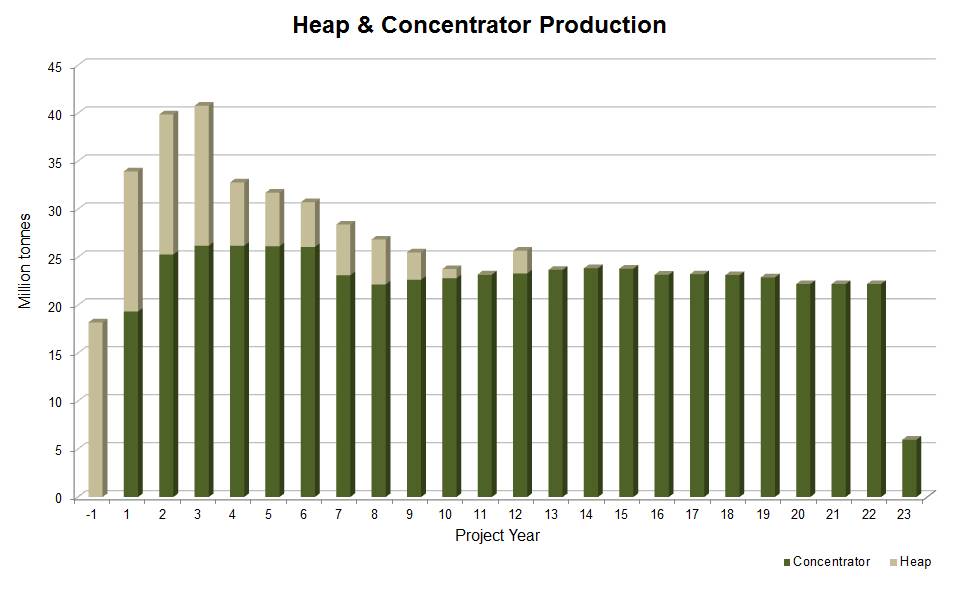

Oxide ore containing significant gold and all sulfide ore will be treated in a concentrator at 60,000 tpd. The concentrator process will consist of crushing, grinding, gravity concentration of free gold, and flotation of sulfide copper. An agitated leach circuit will leach oxide copper from flotation tails. Oxide ore containing little or no gold will be treated in a heap leach at 40,000 tpd. The heap leach process will consist of crushing, agglomeration, and leaching utilizing on-off cells. |

||||||||||||||||||||||||||||

*Four years of mill production. Mill plant starts 9-12 months after Heap Leach

Production

Geology

The King-king Copper-Gold Project is a gold-rich porphyry copper deposit located in the Compostela Valley on the island of Mindanao in the Philippines.

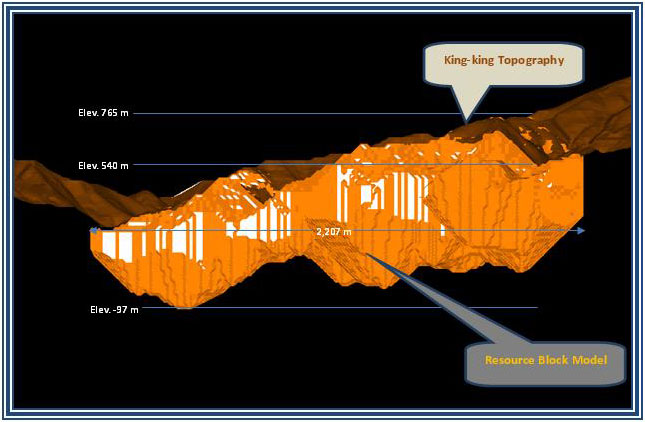

The King-king deposit is a porphyry copper-gold deposit hosted primarily by porphyritic hornblende diorites, submarine volcanic rocks, and volcanoclastic sediments. The intrusive rocks are believed to be Miocene in age, while the volcanic wall rocks are Cretaceous to early Tertiary. Copper and gold mineralization occurs at or near the apex of the composite diorite intrusive complex within the intrusive rocks and extends well into the surrounding wall rocks.

The majority of the sulfide copper mineralization in the King-king deposit consists of chalcopyrite and bornite, with lesser amounts of chalcocite, digenite, and covellite. Rapid regional uplift and erosion likely caused the nearly complete removal of a classical leached cap and eroded or prevented the development of typically thick oxide and supergene enriched zones such as those found in other major porphyry deposits. Copper mineralization in the oxide zone is observed in silicates and phosphates. Copper silicates are the most abundant oxide mineral group present, with copper silicates minerals containing MgO and FeO being the most prevalent of this group in the oxide zone.

Gold is relatively abundant in the oxide zone, in free form formerly in association with the original copper and iron sulfides before they oxidized. Gold also occurs in the sulfide zone of the deposit in free form in close association with bornite and as exsolution intergrowths in other sulfides, particularly pyrite and chalcopyrite. Native gold is occasionally observed on fractures and in quartz veinlets.

In general terms, the King-king gold-copper deposit is consistent in type and form with other bulk-tonnage copper-gold porphyry deposits of the Philippines and elsewhere in the world. The deposit is low in pyrite, averaging less than one percent by volume FeS2. This is reflected by the relative absence of a pyrite halo that is commonly developed around many porphyry copper deposits. For process development purposes, two types of mineralization are considered: sulfide and oxide (which includes mixed oxide-sulfide material).

Learn More

| King-king Technical Report NI43-101 Preliminary Feasibility Study | March 2016 Investor Presentation | Process Flow Diagram |